Procurement Resource Analyses the Production Cost of Laurolactam in its New Report

Analyses Overview of The New Production Cost Report of Laurolactam

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Laurolactam. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Laurolactam production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

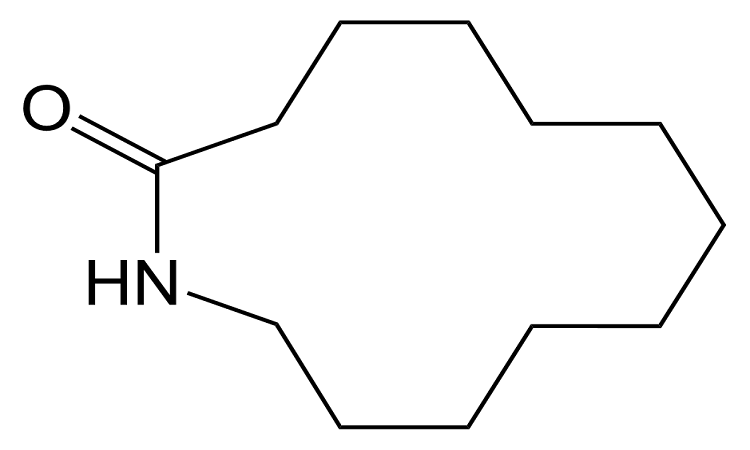

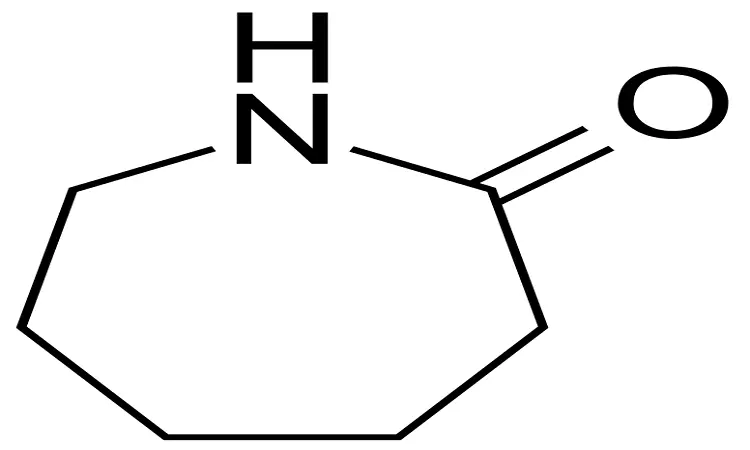

Laurolactam is a macrocyclic lactam that belongs to the category of chemical compounds known as lactams. It is a crystalline, water-insoluble substance that is commonly beige in technical quality and white when pure. It dissolves in a variety of organic solvents, including 1,4-dioxane, benzene, and cyclohexane. The purification of laurolactam has historically been accomplished using multistage distillation at lower pressure. The finest caprolactam is obtained via distillation and crystallisation by solution or melt.

Factors Impacting the Laurolactam Production Cost:

Laurolactam is largely utilised in engineering polymers such as nylon-12 and copolyamides as a monomer. The monomer laurolactam is polymerized to nylon-12 by ring-opening polymerization. Cationic or anionic initiators, and water, can be used to start the reaction. The beginning of O-protonation is thought to be part of cationic polymerization with acid. The polyamide is formed by the monomer’s nucleophilic assault on the reactive protonated nitrogen, followed by sequential ring-opening acylation of the primary amine. PA (polyamide) 12 is a material used in the construction of oil and gas pipelines. Polyamide 12 can withstand mechanical stress, stress fracture, and chemicals like crude oil. Drilling firms can use these qualities to protect gas pipes against corrosion and pollutants. Fatal fractures and the creep and stress rupture process are two key issues with thermoplastic materials used in oil and gas pipelines. PA 12 pipes have a substantially greater hydrostatic strength than High-density polyethylene (HDPE) and grade PE 100 pipes due to intermolecular forces. These factors are expected to impact the production cost of Laurolactam.

Procurement Resource Assessment of Laurolactam Production:

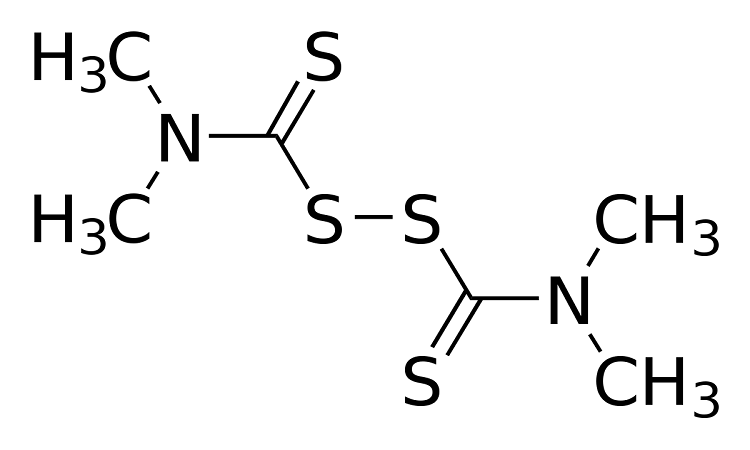

The cost structure of laurolactam manufacturing from cyclododecane is shown in this report. The procedure is broken down into many phases. The first step is to convert cyclododecane to cyclododecanol. The cyclododecanol is dehydrogenated to generate cyclododecanone in the second step. The oximation of cyclododecanone follows these stages. Finally, the oxime is rearranged to generate laurolactam.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/