Procurement Resource Analyses the Production Cost of Vinyl Acetate in its New Report

Analyses Overview of The New Production Cost Report of Vinyl Acetate

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Vinyl Acetate. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Vinyl Acetate production costs, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

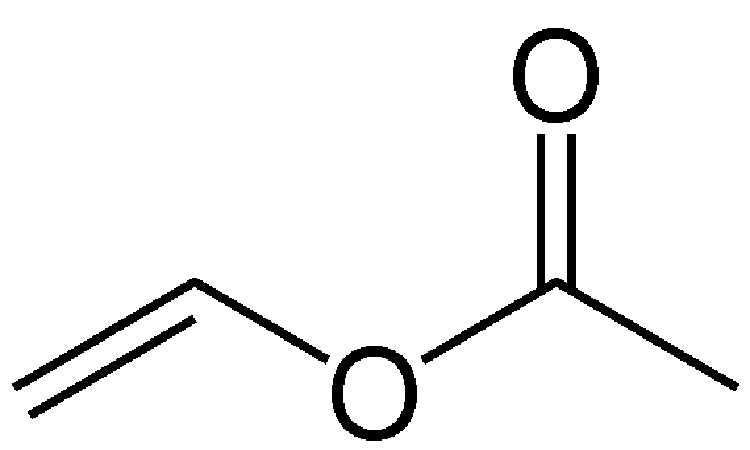

The formula for vinyl acetate (VAM), an organic molecule, is C4H6O2. It is a predecessor of polyvinyl acetate, which is a common industrial polymer. In addition, it is an important component of furniture glue. VAM is made commercially by combining ethylene, acetic acid, and oxygen in the presence of a palladium catalyst.

Factors Impacting the Vinyl Acetate Production Cost:

The demand for vinyl acetate is being driven by the expansion of important downstream applications such as polyvinyl acetate, polyvinyl alcohol, and ethylene-vinyl acetate. Ethylene-vinyl alcohol is the product’s fastest-growing end-use sector. EVA resins are also utilised in the manufacture of packaging film, foam, wires, and cables, hot melt adhesives, and the encapsulation of photovoltaic (PV) modules in solar cells. Over the projected period, rising demand for photovoltaic panels, which are utilised in solar energy generation, is likely to increase demand for the product. These factors are expected to impact the production cost of Vinyl Acetate.

Procurement Resource Assessment of Vinyl Acetate Production:

Procurement Resource’s manufacturing cost analysis examines the cost of making vinyl acetate from acetic acid, ethylene, and acetylene. A typical vapor-phase oxidation method is used to convert acetic acid and ethylene in the manufacturing of vinyl acetate. It is made using a supported noble metal catalyst catalysing the vapour phase reaction of acetic acid with ethylene and oxygen in a fixed bed tubular reactor. The reaction takes place at a temperature of 175-200 degrees Celsius and a pressure of 5-9 bar. Condensation and washing are used to recover vinyl acetate, which is then refined by distillation. Similarly, acetic acid and acetylene are used in the synthesis of vinyl acetate. Dietilene diacetate is formed in this technique when acetylene reacts with acetic anhydride in a catalysed media at a high temperature. The resultant product is subsequently cracked to produce acetic acid and vinyl acetate in a cracking tower.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/