Procurement Resource Analyses the Production Cost of Synthetic Menthol in its New Report

Analyses Overview of The New Production Cost Report of Synthetic Menthol

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Synthetic Menthol. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Synthetic Menthol production cost, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

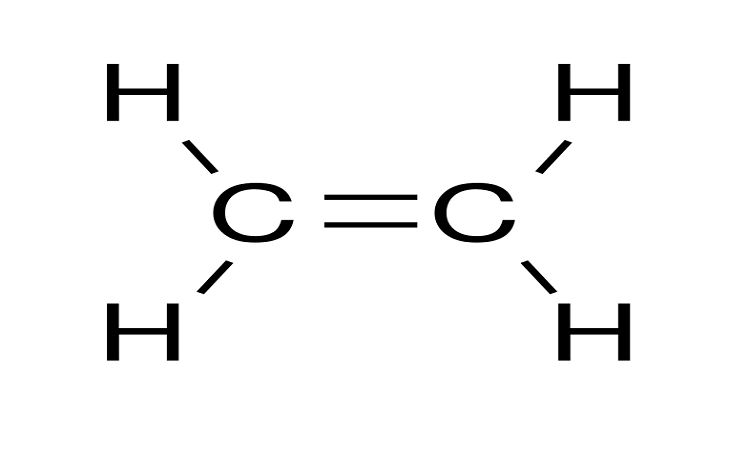

Unlike natural menthol, synthetic menthol is created using petrochemicals such as m-cresol. It takes the form of a waxy, crystalline material that is clear or white in colour. At room temperature, it is solid. Synthetic menthol is used to alleviate mild throat discomfort since it possesses anaesthetic and anti-irritant properties.

Factors Impacting the Synthetic Menthol Production Cost:

Menthol is utilised in a variety of confectionery items such as chewing gums and sweets because of its great medicinal and nutritional value. It is also used in medications, such as ointments and inhalation treatments. Menthol is traditionally obtained by gathering and processing mint leaves. Variations in climatic circumstances, on the other hand, tend to alter the total menthol supply and cause price volatility. India and China currently account for a considerable portion of the world’s natural menthol supply. Over the last decade, the demand for menthol crystals from key end-use sectors has steadily increased.

To fulfil this rising demand, efforts have been focused on the introduction of a new synthetic source for commercial menthol manufacturing. When compared to natural menthol, synthetically generated menthol is purer. In addition, menthol obtained synthetically is less expensive than menthol acquired natively. Furthermore, the availability of raw materials necessary for synthetic menthol synthesis is plentiful, assuring production uniformity. As a result, synthetic menthol has become a feasible substitute for natural menthol. Natural menthol currently accounts for the majority of global menthol use. Synthetic menthol consumption, on the other hand, is predicted to expand at a quicker rate throughout the projection period.

Procurement Resource Assessment of Synthetic Menthol Production:

The production cost report by Procurement Resource assesses the production of Synthetic Menthol from m-cresol via hydrogenation, known as the Haarmann–Reimer process. In this procedure, propene is used to alkylate m-cresol to thymol, which is then hydrogenated to generate the reaction mixture. Fractional distillation is used to remove racemic menthol from the reaction mixture, resulting in synthetic menthol.

A full-cost study of synthetic menthol manufacturing from pulegone utilising the hydrogenation technique is also included in this research. To generate racemic or synthetic menthol, pulegone is hydrogenated in the presence of different catalysts such as platinum, rhodium, palladium, and others in a hydrogenator (hydrogenation reactor) at high temperature and pressure. A full-cost study of synthetic menthol manufacture from myrcene utilizing an asymmetric synthesis technique is also included in this research. First, an allylic amine is created from myrcene, which is then hydrolyzed before being asymmetrically isomerized with a BINAP rhodium complex to yield R-citronellal (which is enantiomerically pure). This is then cyclized again using zinc bromide in a carbonyl-ene process to yield isopulegol. Finally, the isopulegol is hydrogenated to yield synthetic menthol as the end product.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/