Procurement Resource Analyses the Production Cost of Recycled HDPE in its New Report

Analyses Overview of The New Production Cost Report of Recycled HDPE

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Recycled HDPE. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Recycled HDPE production costs, looking into the capacity expansions, plant turnarounds, mergers, and looking into capacity expansions, plant turnarounds, and mergers, acquisitions, and investments.

Product Definition:

Recycled plastics are created from leftover or discarded plastic and are employed to produce concrete, storage containers, and PVC windows for the building and packaging, automotive, construction, electrical and electronics, and textile industries. The goal of recycling plastics is to decrease the pollution that occurs during the production of new or virgin plastics. The plastic recycling method aids in the resolution of plastic disposal issues. According to Plastic Oceans International, more than 300 million tonnes of plastic are produced each year, resulting in huge demand for plastic reuse, recovery, and recycling.

Factors Impacting the Recycled HDPE Production Cost:

The expansion of this market has been aided by factors such as increased demand for plastics in different end-user sectors and favourable government efforts aimed at reducing plastic waste. Plastic producers are primarily concentrating on creating innovative recycling solutions to minimise greenhouse gas emissions and preserve environmental sustainability as awareness of global warming grows. Conversely, the market’s expansion has been impeded by the rising usage of virgin plastics and the lack of a proper plastic collecting infrastructure. This market has a hurdle since there is no established solid waste collection and sorting infrastructure. Because of its cheap costs, the Plastic Recycling industry is seeing an increase in demand for recovered PET and HDPE. These factors are expected to impact the production cost of Recycled HDPE.

Procurement Resource Assessment of Recycled HDPE Production:

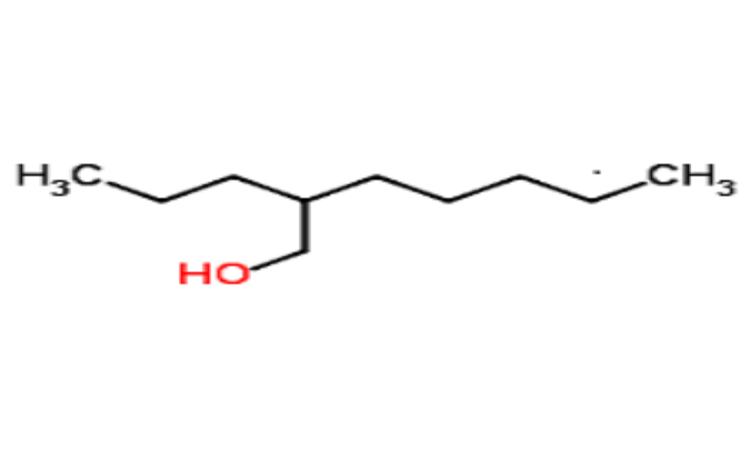

The production cost report by Procurement Resource assesses the production of Recycled HDPE via waste HDPE. In this process, the plastic is classified and cleaned to remove the dirt and waste, so that only HDPE can be processed. It, then, undergoes a granulation process in which HDPE is chopped finely and melted into pellets or granules. The pellets and granules are combined together through several processes to obtain recycled HDPE.

We Provide Lots of Industries Reports With Full Analysis, For That You Should Visit Our Procurement Resource Website, Apart From This, We Also Provide the Latest Price Trends of Various Products Including Ethylene Price, Barley Price and Sunflower Seed Price.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/