Procurement Resource Analyses the Production Cost of Polycarbonate in its New Report

Analyses Overview of The New Production Cost Report of Polycarbonate

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Polycarbonate. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Polycarbonate production costs, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and invents.

Product Definition:

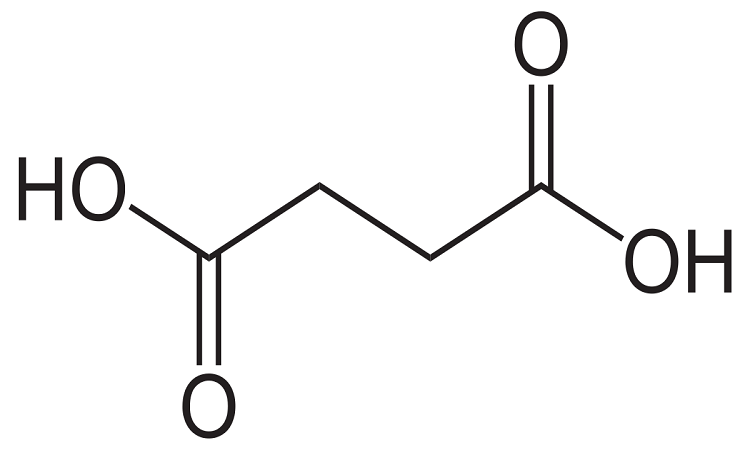

Polycarbonate, a form of polyester is made of phenyl, carbonate, and two methyl groups formed via a reaction between bisphenol-A and carbonyl chloride. They are technical materials that are solid and robust, and certain grades are optically clear. They arareto mould, thermoform, and work with. Because of their properties, polycarbonates have a wide range of applications. This translucent plastic is used in shatter-resistant windows, lightweight eyeglass lenses, packaging, interior cladding, outdoor glazing, roofing designs, automotive, electrical, and electronics, and personal security applications. Depending on the use, it comes in a number of grades.

Factors Impacting the Polycarbonate Production Cost:

The expanding trend of materials used in the automobile industry is propelling the industry forward. The commodity is employed to manufacture several items, in the electrical and electronics sectors. Regulatory requirements are pressuring automakers to use plastics to reduce car weight and improve fuel efficiency, which is aiding growth. Other reasons, such as the widespread use of polycarbonate in agriculture for UV-resistant roof panels and sheets in agricultural outbuildings, and intensive research and development (R & R&D) initiatives to produce high-performance polymers, are likely to fuel the market even more. Manufacturers are expected to benefit from product enhancements for medical applications and the expanding commercialization of the bio-polycarbonate sector in the future.

Procurement Resource Assessment of Polycarbonate Production:

The production cost report by Procurement Resource assesses the production of Polycarbonate from bisphenol A (BPA or Bis-A) and carbonyl chloride via condensation polymerization. This procedure produces a bisphenol A solution in sodium hydroxide, which is then combined with a carbonyl chloride solution dissolved in an organic solvent such as dichloromethane. Polymerization is then carried out with the assistance of a catalyst (essentially an amine). The aqueous layer is removed once the polycarbonate is produced in an inorganic layer. The resulting product is evaporated, resulting in the creation of polycarbonate (polymer). A full cost study of polycarbonate manufacturing from bisphenol A (BPA or Bis-A) and diphenyl carbonate is also included in this research. Polymerization is achieved using the Melt process, which involves the transesterification of diphenyl carbonate (DPC) with bisphenol-A. The resulting product is undiluted and may be pelletized to produce polycarbonate.

We Provide Lots of Industries Reports With Full Analysis, For That You Should Visit Our Procurement Resource Website, Apart From This, We Also Provide the Latest Price Trends of Various Products Including Potato Price, Chloroform Price and Kerosene Price.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/