Procurement Resource Analyses the Production Cost of Nylon-6,6 in its New Report

Analyses Overview of The New Production Cost Report of Nylon-6,6

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Nylon-6,6. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Nylon-6,6 production cost, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

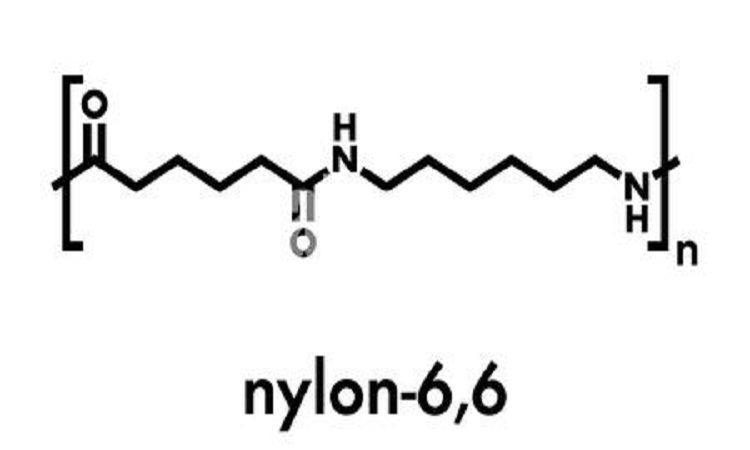

Nylon-6,6, often known as Nylon 66, is a polyamide or nylon material. Hexamethylenediamine and adipic acid, which give nylon-6,6 its name, are made up of two monomers, each with six carbon atoms. Polycondensation of hexamethylenediamine with adipic acid produces nylon-6,6. In a reactor, equal volumes of hexamethylenediamine and adipic acid are mixed with water. Nylon salt, an ammonium/carboxylate combination, is made by crystallizing this. The nylon salt is placed in a reaction vessel, where the polymerization process is carried out either in batches or continuously. The creation of amide bonds from the acid and amine functions leads the process towards polymerization by removing water. As a result, molten nylon-6,6 is created. At this point, it can be extruded or granulated, or immediately spun into fibers by extrusion via a spinneret (a tiny metal plate with fine pores) and chilling to make filaments.

Factors Impacting the Nylon-6,6 Production Cost:

Nylon 66 is a widely utilised technical thermoplastic that is widely used in the automotive sector. High elasticity, exceptional tensile strength, and abrasion resistance are among the mechanical features of such materials. Nylon 66, on the other hand, has a stronger temperature resistance capability, making it a popular material for a variety of high-temperature applications. The worldwide nylon 66 market is being driven by such factors. Nylon 66 is widely used in the polyamide, textile, and electronics industries, in addition to the automobile sector, because of its high electrical resistance, hardness, and strong insulating qualities. The increased adoption of nylon 66 in numerous sectors is also propelling the global nylon 66 market forward.

Procurement Resource Assessment of Nylon-6,6 Production:

Procurement Resource’s manufacturing cost study evaluates the synthesis of Nylon-6,6 from adipic acid and hexamethylenediamine. Adipic acid and hexamethylenediamine are used in the production of Nylon-6,6. This is an example of a continuous polymerization process.

Procurement Resource’s manufacturing cost analysis also evaluates nylon-6,6 synthesis using a mass technique. Adipic acid and hexamethylenediamine are used in the production of Nylon-6,6. A batch polycondensation method is what this is.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/