Procurement Resource Analyses the Production Cost of Methyl Methacrylate in its New Report

Analyses Overview of The New Production Cost Report of Methyl Methacrylate

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Methyl Methacrylate. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Methyl Methacrylate production cost, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

Polymethyl Methacrylate (PMMA) is made from a vast amount of methyl methacrylate across the world (approximately 50 percent of global production). The automobile industry uses polymethyl Methacrylate to make a range of parts and components, including the exterior, rear, and indicator light covers; ornamental trims; ambient lighting; door entry strips; vehicle glass, and so on. PMMA is the most perfect resin for the Automotive sector because of its main characteristics, such as lightweight, good scratch resistance, and low-stress birefringence, among others.

Factors Impacting the Methyl Methacrylate Production Cost:

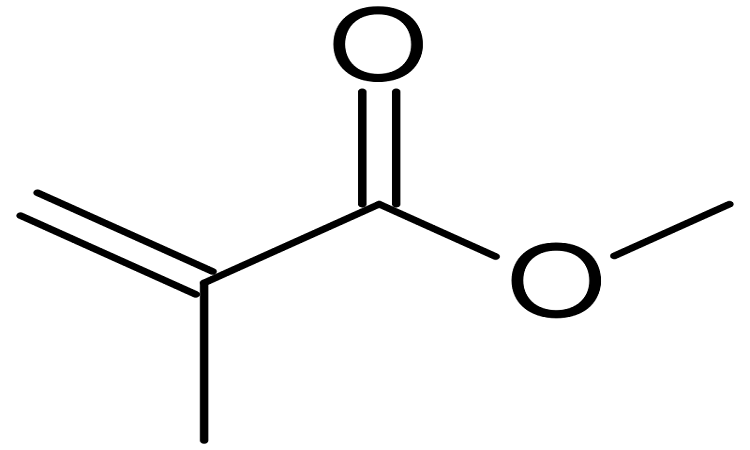

CH2=CCOOCH3 is the formula for methyl methacrylate, a chemical molecule. The methyl ester of methacrylic acid, a white liquid, is a monomer used to make polymers on a massive scale. This factor is expected to impact the production cost of Methyl Methacrylate.

Procurement Resource Assessment of Methyl Methacrylate Production:

Procurement Resource’s production cost report evaluates the manufacturing of Methyl Methacrylate using the acetone cyanohydrin (ACH) pathway, which involves the oxidation of t-butanol and methanol. The acetone cyanohydrin (ACH) method was used in the first production process of methyl methacrylate from acetone. Acetone and hydrogen cyanide are combined to make acetone cyanohydrin (ACH), which is then hydrolyzed with sulphuric acid to produce a methacrylamide sulphate ester. Methanolysis is used to turn the ester into methyl methacrylate, with ammonium bisulphate as a by-product. The second step in the production of methyl methacrylate is from t-butanol and methanol. T-butanol is first oxidised to create metacrolein, which is then further oxidised to give methacrylic acid. Finally, the generated methacrylic acid undergoes an esterification process with methanol to provide methyl methacrylate. The oxidation process is used in the third production process of methyl methacrylate from isobutylene. Two-stage catalytic oxidation of isobutylene is carried out in this method to create methacrylic acid (MAA), which is then esterified with methanol to form methyl methacrylate.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/