Procurement Resource Analyses the Production Cost of Ethylene in its New Report

Analyses Overview of The New Production Cost Report of Ethylene

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Ethylene. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Ethylene production costs, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

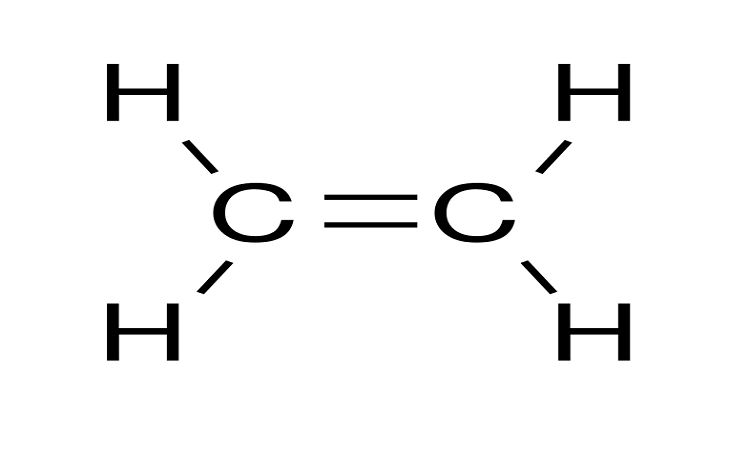

Ethylene is a combustible, colorless gas with a musky odor. After acetylene, it is the simplest alkene and unsaturated hydrocarbon. It is widely utilised in agriculture as a ripening hormone for plants. It is also used to make ethyl benzene, polyethylene, ethylene dichloride, and ethylene oxide in the chemical industry.

Factors Impacting the Ethylene Production Cost:

The expanding global working population has produced a need for packaged meals and beverages, which is likely to drive the PE industry forward. The rising automotive sector is another factor fueling this company’s expansion. PE is utilised in a variety of applications, including automobile exteriors, electrical insulation, gasoline tanks, and wires and cables. Furthermore, rising investment in the construction and infrastructure sectors is raising demand for PE and associated materials in construction activities, which is likely to drive ethylene market development throughout the forecast period.

Procurement Resource Assessment of Ethylene Production:

The production cost report by Procurement Resource assesses the production of Ethylene from the steam cracking process. A hydrocarbon like ethane and steam are heated to 750–950 ° C in this procedure. It induces unsaturation by converting the big hydrocarbon into a smaller hydrocarbon. The end product is ethylene.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/