Procurement Resource Analyses the Production Cost of Ethanoic Acid in its New Report

Analyses Overview of The New Production Cost Report of Ethanoic Acid

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Ethanoic Acid. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Ethanoic Acid production costs, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

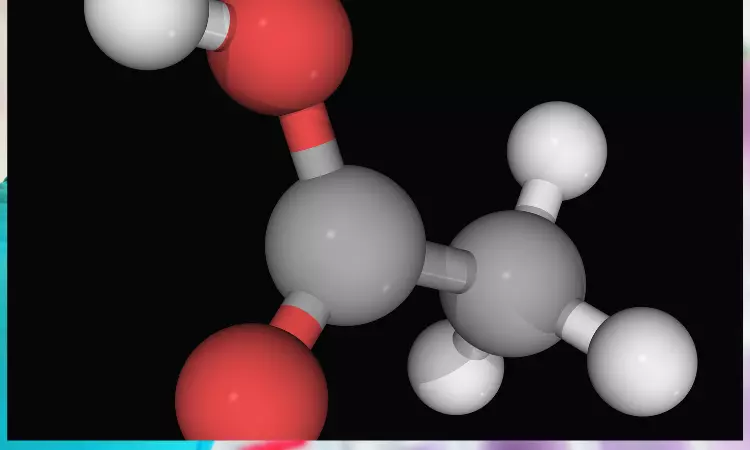

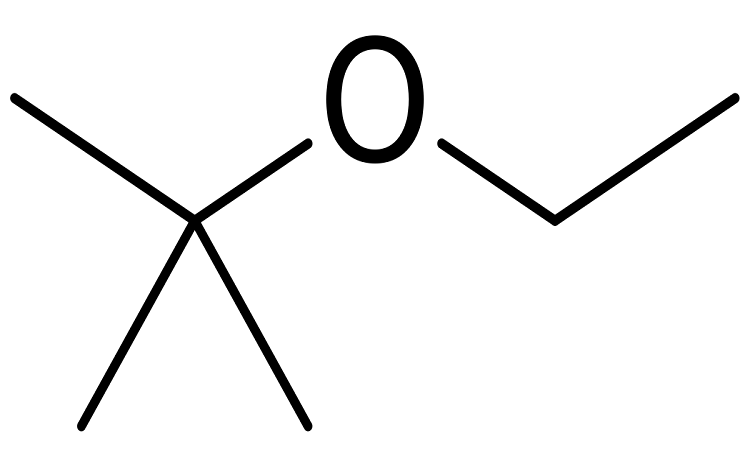

Ethanoic acid, often known as acetic acid, is a white liquid with a strong distinctive, and unpleasant odour. Acetic acid is mostly created by the methanol carbonylation process, in which carbon dioxide and methanol combine to form acetic acid.

Factors Impacting the Ethanoic Acid Production Cost:

Because acetic acid is one of the key contributors to the manufacturing of VAM, it is projected to boost the overall acetic acid market. Vinyl alcohols and polyvinyl acetates are in high demand, which is propelling the acetic acid market forward. VAM is also applied to create polymer for coatings and adhesives, which implies that acetic acid requirement will soar. As the global population grows, so does the need for garments and other packaged goods, which is driving the expansion of the packaging and textile sectors that use PTA, and so contributing to the total acetic acid market growth throughout the projection period. These factors are expected to impact the production cost of Ethanoic Acid.

Procurement Resource Assessment of Ethanoic Acid Production:

Procurement Resource’s production cost report evaluates ethanoic acid production by oxidation, fermentation, and carbonylation. In the first step of the ethanoic acid synthesis process, numerous chemical substances such as n-butane, ethane, acetaldehyde, and oxygen are used in the oxidation process. Acetaldehyde and other unreacted chemicals are condensed and recycled back into the reactor. To recover the ethanoic acid, the liquid product is delivered to a set of distillation columns. The fermentation method is used in the second step of the ethanoic acid manufacturing process. Fermentation takes place in a tower filled with wood shavings or charcoal in this method. Air is provided from the bottom and the alcohol-containing supply is worked its way to the top of the tower. The improved air supply cuts the time it takes to make vinegar from months to weeks. Methanol and carbon monoxide is made to react with one another to make acetic acid in the third carbonylation process. Iodomethane is used as an intermediary in the technique, which is divided into three phases. A metal carbonyl catalyst is required for carbonylation. Ethanoic acid is obtained at the end of the procedure.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/