Procurement Resource Analyses the Production Cost of DMC in its New Report

Analyses Overview of The New Production Cost Report of DMC

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of DMC. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labour wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence DMC production costs, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

Product Definition:

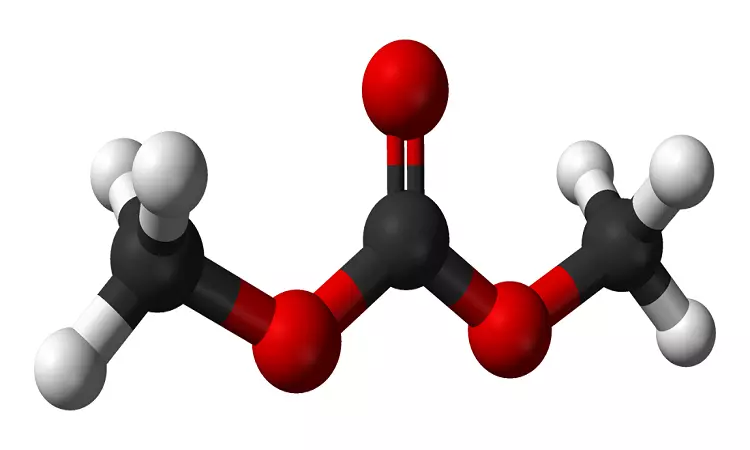

Dimethyl carbonate is a versatile chemical with favourable properties such as high solubility and low toxicity. It has a pale look and is combustible, odourless, and inflammable. It has a high degree of reactivity with other compounds.

Factors Impacting the DMC Production Cost:

Polycarbonate is widely used in a variety of sectors, including electronics, automobiles, consumer products, construction, and many more. Due to features such as transparency, strength, heat resistance, and chemical resistance, the dimethyl carbonate market is predicted to grow due to rising demand in the electronics and automotive industries. Furthermore, the rise in the vehicle sector in countries like India, China, and Japan has supported dimethyl carbonate market growth. Moreover, the growing need for low-cost and efficient consumer products, including laptops, smartphones, smart speakers, smart home devices, power banks, and other items, drives the dimethyl carbonate market ahead. These factors are expected to impact the production cost of DMC.

Procurement Resource Assessment of DMC Production:

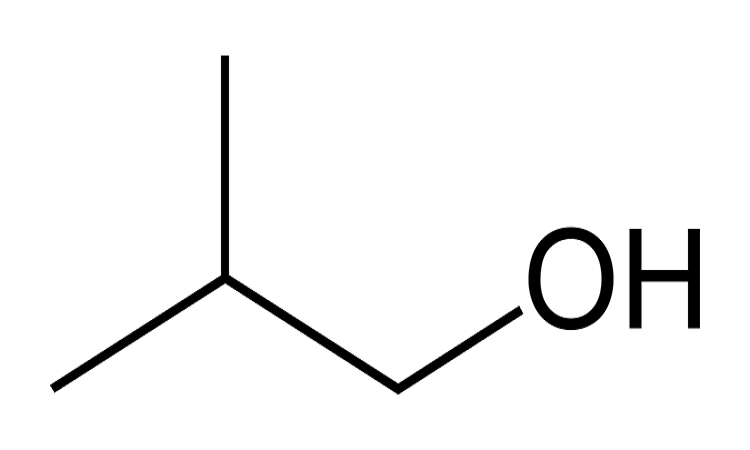

Procurement Resource’s production cost report evaluates the cost of producing DMC via oxidative carbonylation, transesterification, catalytic redox process, and phosgene and methanol. In the first production process of DMC via oxidative carbonylation, a reaction among methanol, carbon monoxide, and oxygen (or any other oxidiser) is carried out in a liquid phase in a reactor in the presence of a catalyst, namely, copper chloride (CuCI), which produces a heterogeneous mixture in a vapour phase. The mixture so produced is partially condensed, treated for catalyst recovery, and further refined using the distillation process. The unreacted methanol is recovered for reusability, following the separation of side products to finally obtain pure DMC.

In the second production process of DMC via transesterification, the reaction between ethylene carbonate and methanol is carried out in a reactive distillation column to produce dimethyl carbonate (DMC) and ethylene glycol. The products obtained undergo extractive distillation to finally produce pure DMC with monoethylene glycol as the by-product. In the third production process of DMC via the catalytic redox process, methyl nitrite is carbonylated in the gas phase in the presence of palladium as a catalyst to produce DMC. In the fourth production process of DMC from phosgene and methanol, phosgene and methanol react to form an intermediate, namely, methyl chloroformate, which is further converted to produce DMC.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Procurement Resource

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/