Procurement Resource Analyses the Production Cost of Acetic Anhydride in its New Report

Analyses Overview of The New Production Cost Report of Acetic Anhydride

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Acetic Anhydride. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Acetic Anhydride production cost, looking into capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

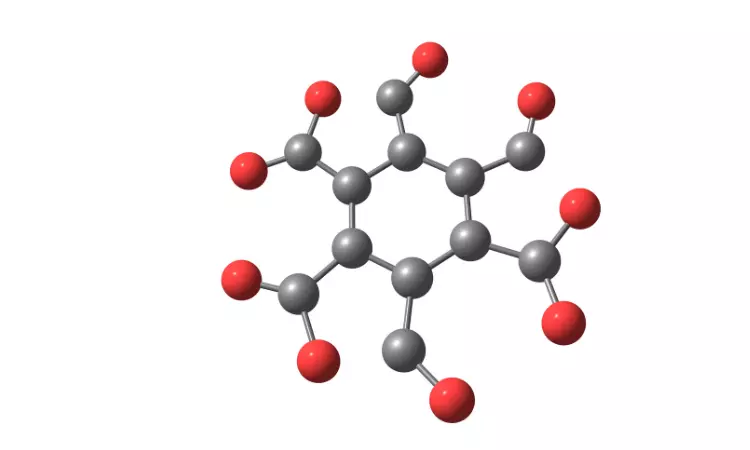

Product Definition:

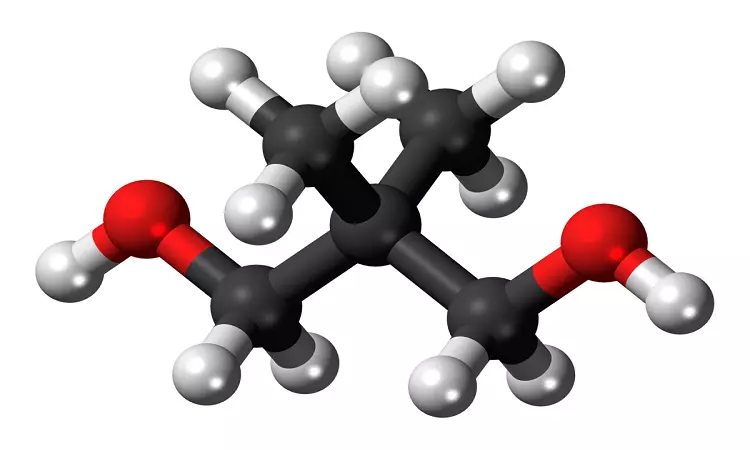

Acetic anhydride is the most basic carboxylic acid anhydride, and it’s utilized to make a variety of items. Cellulose Acetate is primarily made from Acetic Anhydride as a raw material. It is also used in the manufacture of aspirin and tetraacetylethylenediamine (TAED), a common ingredient in laundry detergents. Commercially, there are two ways to make acetic anhydride. The ketene-acetic acid technique is an industrially feasible approach. It entails the thermal breakdown of acetic acid to ketene, followed by a reaction of the ketene with more acetic acid to produce acetic anhydride. Carbonylation of methyl acetate is a second method. Carbonylation of methyl acetate produces acetic acid as a byproduct.

Factors Impacting the Acetic Anhydride Production Cost:

Aspirin, sulfa medicines, certain vitamins and hormones, acetyl-p-aminophenol, cortisone, acetanilide, theophylline, acetylcholine hydrochloride, acetophenacetin, sulfonamides, and paracetamol are all made with acetic anhydride as a raw material. Fever, cough, and cold, as well as physical pains, nausea, and other general health issues, have grown drastically globally. As a result, demand for pain relievers such as aspirin and paracetamol has risen. The rising use of generic pharmaceuticals has helped the acetic anhydride business significantly. Furthermore, the pharmaceutical business has seen significant growth in recent years. Due to a rise in people’s health worries, the increasing trend is projected to continue over the forecasted period.

Procurement Resource Assessment of Acetic Anhydride Production:

The Eastman method, which includes reacting a combination of methyl acetate and carbon monoxide in the presence of a rhodium catalyst and one or more promoters, is assessed in the production cost report by Procurement Resource.

Also Check – Acetic Anhydride Production from Acetic Acid and Acetone, Acetic Anhydride Production from Acetic Acid and Acetic Anhydride Production from Methyl Acetate.

A cost study of Acetic Anhydride generated by the ketene technique is also included in this publication. Acetic anhydride is formed when acetic acid is dehydrated to ketene, which reacts with acetic acid in a cracking furnace with triethyl phosphate as a catalyst to generate acetic anhydride.

The report also includes an analysis of Acetic Anhydride production utilising a two-step technique. Pyrolysis converts acetone to ketene, which subsequently reacts with acetic acid to generate Acetic Anhydride.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/