Procurement Resource Analyses the Production Cost of Methionine in its New Report

Analyses Overview of The New Production Cost Report of Methionine

The new report by Procurement Resource, a global procurement research, and consulting firm, looks in-depth into the costs involved in the production of Methionine. The comprehensive report analyses the production cost of the material, covering the raw material costs and co-product credit, equipment costs, land and site costs, labor wages, maintenance costs, financing charges, and depreciation costs. The extensive study describes the stepwise consumption of material and utilities along with a detailed process flow diagram. The report also assesses the latest developments within the industry that might influence Methionine production cost, looking into the capacity expansions, plant turnarounds, mergers, acquisitions, and investments.

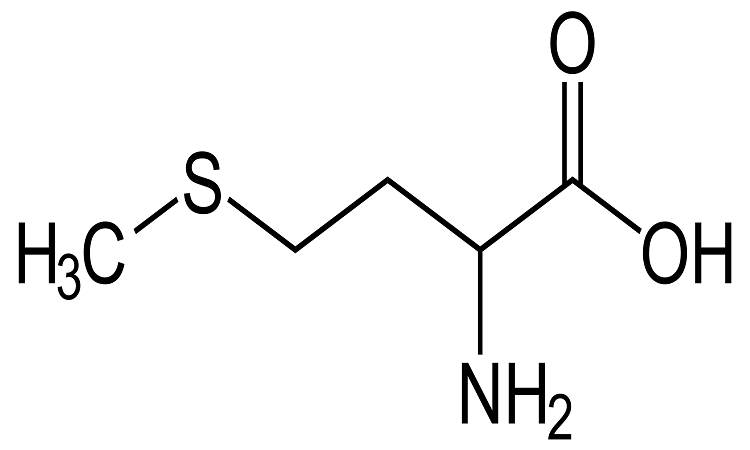

Product Definition:

Methionine is a sulphur-containing amino acid. Amino acids help in the production of protein in the human body. Items like meat, fish, and dairy items all comprise methionine. It plays a crucial part in the body’s numerous functions. D-methionine and L-methionine are the two most common types of methionine. DL-Methionine is an important amino acid that functions as a building block in the formation of proteins. It is a mixture of D-methionine and L-methionine. Because feed is such an essential aspect in the meat business, where profit is heavily reliant on productivity at the lowest feasible feed costs.

Factors Impacting the Methionine Production Cost:

The greatest consumer of Methionine is animal feed additive, which is expected to maintain its dominance during the projection period, accounting for nearly three-quarters of worldwide demand. The increase can be ascribed to increasing demand for Methionine in aquafeed, as well as an increase in global demand for fish flesh. Nevertheless, poultry is the major consumer of DL-Methionine since it prevents feathering issues triggered by a lack of essential nutrients in birds. Because animals cannot generate methionine on their own, animal feed is expected to lead to worldwide Methionine consumption throughout the projection period.

Procurement Resource Assessment of Methionine Production:

The production cost report by Procurement Resource assesses the production of Methionine from methional and hydrogen cyanide (HCN) using the carbonate process. The interaction between methional and hydrogen cyanide produces an intermediate, hydantoin, which is then reacted with potassium carbonate to make potassium methionine, which is then converted to produce DL-methionine.

A full cost study of L-methionine synthesis from raw sugar utilising the direct fermentation technique is also included in this research. Raw sugar is diluted in this procedure, after which it is hydrolyzed to create glucose and fructose (invert sugars). Finally, the invert sugars are fermented directly, yielding L-Methionine powder and methionine solution.

This paper also includes a cost analysis of the manufacture of methionine hydroxy analogues from methional and hydrogen cyanide (HCN). In this procedure, the reaction between methional and hydrogen cyanide produces an intermediate, hydroxy methylthiobutyronitrile (HMBN), which is then hydrolyzed to yield a methionine hydroxy analogue.

In addition, this paper discusses a full cost analysis of the carbonate method for producing DL-methionine from methional and hydrogen cyanide (HCN). The interaction between methional and hydrogen cyanide produces an intermediate, hydantoin, which is then reacted with potassium carbonate to make potassium methionine, which is then converted to produce DL-methionine.

Furthermore, a full cost study of methionine hydroxy analogue generation from acrolein, methyl mercaptan, and hydrogen cyanide is included in this research (HCN). The interaction between acrolein and methyl mercaptan produces methional in this mechanism. As an intermediary, the methional generated interacts with hydrogen cyanide to form hydroxy methylthiobutyronitrile (HMBN). The intermediate is then hydrolyzed, followed by the separation of water and products from the reaction medium using solvent extraction, yielding methionine hydroxy analogue as the end product.

Another, full-cost study of DL-methionine manufacturing using propylene, methyl mercaptan, and hydrogen cyanide is also incorporated in this research (HCN). The oxidation of propylene to create acrolein is carried out in this process. Methional is formed when acrolein interacts with methyl mercaptan, which then reacts with hydrogen cyanide to make methionine.

This paper also includes a full economic analysis of the carbonate method for producing DL-methionine from methyl mercaptan, acrolein, and hydrogen cyanide (HCN). MMP is produced via a reaction between refined acrolein and methyl mercaptan in this mechanism (or methional). MMP is generated, which then interacts with hydrogen cyanide to form DL-Methionine.

About Us:

Procurement Resource ensures that our clients remain at the vanguard of their industries by providing actionable procurement intelligence with the help of our expert analysts, researchers, and domain experts. Our team of highly seasoned analysts undertake extensive research to provide our customers with the latest and up-to-date market reports, cost-models, price analysis, benchmarking, and category insights, which aid in simplifying the procurement process for our clientele. We work with a diverse range of procurement teams across industries to get real-time data and insights that can be effectively implemented by our customers. We also track the prices and production costs of an extensive range of goods and commodities, thus, providing you with the updated and reliable data. We, at Procurement Resource, with the help of the latest and cutting-edge techniques in the industry, help our clients understand the supply chain, procurement, and industry climate, so that they can form strategies which ensure their optimum growth.

Contact Us:

Company Name: Claight Corporation

Contact Person: Chris Smiths

Email: sales@procurementresource.com

Toll Free Number: USA & Canada: +1-415-325-5166 | Europe & Africa: +44-702-402-5790 | APAC: +91-8586081494

Address: 30 North Gould Street, Sheridan, WY 82801, USA

Blog – https://procurementresource.blogspot.com/

Website: https://www.procurementresource.com/